Unveiling the Art of 45-Degree Assembly in Aluminum Alloy Frames

1. Introduction

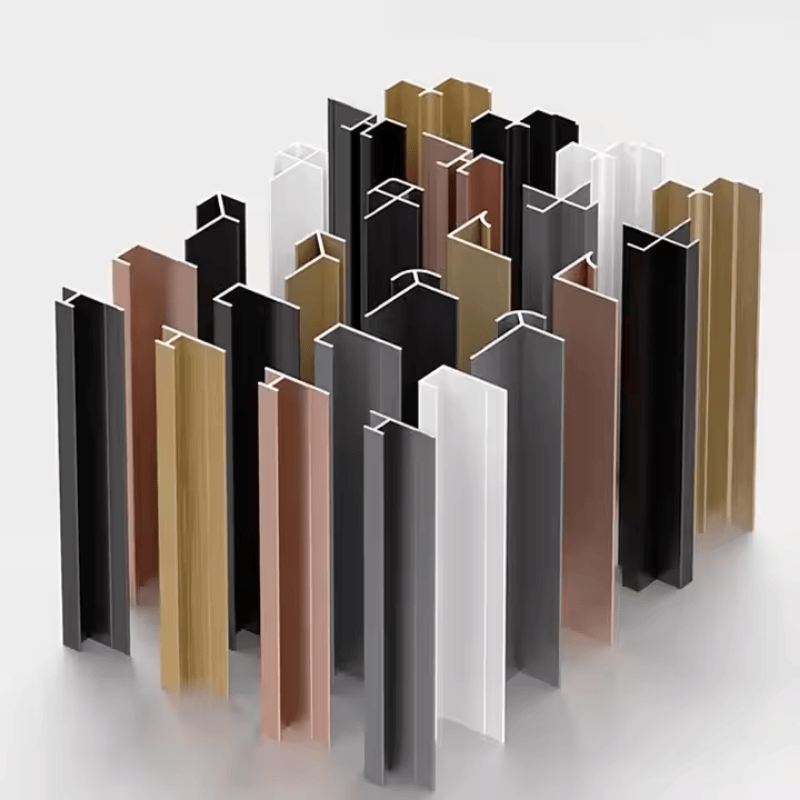

In the realm of decorative framing for mirrors, photos, and paintings, 45 - degree assembled aluminum alloy frames have emerged as a symbol of precision and elegance. This article delves into the intricate 45 - degree assembly process of aluminum alloy mirror frames, highlighting the importance of accurate cutting and seamless joining. We will also explore the brushing surface - finishing technique, which enhances the aesthetic appeal and durability of these frames. Additionally, five popular colors achieved through brushing—Matte black, Matte silver, Bright Titanium, Purple gold, and Light dumb gold—will be introduced. Finally, we’ll showcase how Aluinno stands out in crafting high - quality 45 - degree assembled aluminum alloy frames, combining craftsmanship with style.

2. The Precision of 45 - Degree Assembly Process

The 45 - degree assembly process of aluminum alloy frames is a testament to the craftsmanship and technical expertise required in the framing industry. Aluminum profiles, carefully selected for their strength and malleability, serve as the building blocks for these frames.

The process begins with precise cutting of the aluminum profiles at a 45 - degree angle. Advanced cutting machines, often computer - numerically controlled (CNC), are utilized to ensure accuracy within extremely tight tolerances. This precision is crucial because even the slightest deviation in the angle can result in gaps or misalignments when the pieces are assembled. After cutting, the edges of the aluminum profiles are often smoothed to remove any burrs or rough spots, which not only improves the appearance but also ensures a snug fit during assembly.

For assembly, various techniques can be employed. One common method is using corner connectors or brackets. These connectors are inserted into pre - drilled holes in the aluminum profiles, providing a secure and stable joint. Another approach is welding, where the 45 - degree cut edges are joined together using specialized aluminum welding equipment. Welding creates a seamless and strong bond, resulting in a frame that is both aesthetically pleasing and highly durable. Whether using connectors or welding, the goal is to create a frame with sharp, clean corners that enhance the overall look of the mirror, photo, or painting it holds.

| Aluminum Frame | |

| Material | Aluminium Alloy 6063 T5 T6 |

| Size | Customized available; |

| Thickness | Customized available; |

| Color | Silver, Black, White, Champagne, Gray, Gold, Rose Gold(Can be customized) |

| Surface treatment | Mill finish, Anodizing, Powder Coating, Wood Grain, Polishing(Can be customized) |

| Usage | mirror frame, picture frame ,painting frame |

| supplier type | Manufacture |

3. The Enchanting Brushing Surface - Finishing Technique

The brushing surface - finishing technique plays a pivotal role in elevating the visual appeal and functionality of 45 - degree assembled aluminum alloy frames. This process involves using abrasive brushes or pads to create a series of fine, parallel lines on the surface of the aluminum. The result is a textured finish that not only looks distinctive but also provides some level of scratch resistance.

3.1 Matte black

Matte black 45 - degree assembled aluminum alloy frames exude an air of sophistication and elegance. The brushing process on aluminum in matte black creates a soft, non - reflective surface that adds a touch of mystery to any decor. This color is perfect for modern, minimalist, or even gothic - inspired interior designs. Its low - key nature allows it to complement a wide range of colors and styles of the framed contents without overpowering them. Moreover, the matte black finish is relatively easy to maintain, as it hides fingerprints and minor smudges well.

3.2 Matte silver

Matte silver frames bring a sleek, contemporary look to mirrors, photos, and paintings. The brushing on aluminum gives the frame a satin - like sheen, creating a subtle yet eye - catching effect. This color pairs harmoniously with industrial, Scandinavian, and other modern design themes. The neutral tone of matte silver makes it a versatile choice, as it can blend seamlessly with both light and dark - colored backgrounds, enhancing the overall aesthetic of the framed piece.

3.3 Bright Titanium

Bright Titanium 45 - degree assembled aluminum alloy frames are a statement of luxury and glamour. The brushing process accentuates the metallic luster of aluminum, resulting in a shiny, reflective surface that catches the light from every angle. Ideal for high - end commercial spaces or luxurious home decor, these frames can transform any mirror, photo, or painting into a centerpiece. Despite its shiny appearance, the aluminum frame with Bright Titanium finish is also quite durable, resistant to scratches and wear.

3.4 Purple gold

Purple gold frames offer a unique and opulent look. The combination of purple and gold hues, enhanced by the brushing process on aluminum, creates a rich, regal appearance. This color is perfect for adding a touch of drama and elegance to traditional, eclectic, or art - deco - inspired interiors. The Purple gold finish not only makes the frame stand out but also provides excellent protection against environmental elements, ensuring its long - lasting beauty.

3.5 Light dumb gold

Light dumb gold frames radiate warmth and charm. The brushing on aluminum gives this color a soft, muted golden tone that is both classic and inviting. Suitable for rustic, Mediterranean, or contemporary decor styles, light dumb gold frames can create a cozy and welcoming atmosphere around the framed items. Its relatively low - maintenance nature, as it doesn't show dirt and marks easily, adds to its appeal.

4. Aluinno: Crafting Excellence in 45 - Degree Assembled Aluminum Alloy Frames

When it comes to 45 - degree assembled aluminum alloy frames, aluinno stands at the forefront of quality and innovation. With a deep understanding of the assembly process and a commitment to using the finest aluminum profiles, Aluinno ensures that each frame is crafted to perfection. Our state - of - the - art cutting and assembly techniques guarantee precise 45 - degree joints, while our diverse range of brushing finishes in popular colors like Matte black, Matte silver, Bright Titanium, Purple gold, and Light dumb gold caters to every design preference. Whether you're looking for a frame for a residential or commercial project, Aluinno offers high - quality 45 - degree assembled aluminum alloy frames that combine style, durability, and functionality.

En

En

Location:

Location: