Unveiling the Mechanical Secrets of 6082 Aluminum at Room Temperature

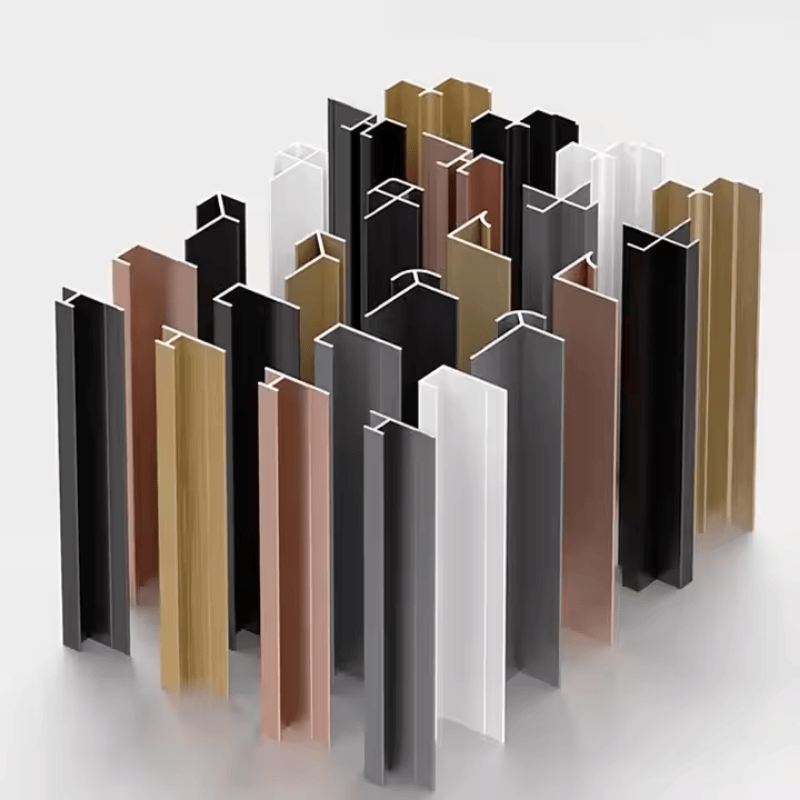

In the fascinating world of aluminum alloys, 6082 aluminum has emerged as a star performer, playing a crucial role in a wide range of applications, especially when it comes to aluminum profiles. This alloy has captured the attention of engineers, architects, and manufacturers alike, owing to its unique combination of properties.

1. Introduction to 6082 Aluminum

6082 aluminum alloy is a member of the 6000 series, renowned for its excellent balance of strength, corrosion resistance, and formability. It is composed of aluminum with carefully selected alloying elements such as magnesium, silicon, and manganese. Originating from extensive research and development efforts, it has become a staple in modern manufacturing, finding its way into everything from high-rise buildings to industrial machinery.

2. Fundamentals of Mechanical Properties

The mechanical properties of a material are the building blocks of its usability. For 6082 aluminum, understanding these properties is essential. Tensile strength measures the maximum stress a material can withstand when pulled apart. It dictates how well the aluminum can endure stretching forces, crucial in applications like structural supports. Yield strength, on the other hand, indicates the point at which the material begins to deform permanently. In the context of window frames, for example, it determines the stability of the frame when subjected to wind loads or the force of opening and closing. Ductility, expressed as elongation, showcases the material's ability to stretch without fracturing, enabling complex shaping during the extrusion process.

3. T4, T5, T6 Tempers: Unraveled

| ALLOY | STATE | Tensile strength (Rm Mpa) |

Non-proportional Stretching Stress (Rp0.2 Mpa) |

Stretching Rate ((A50mm%)) |

| 6082 | T4 | 205 | 110 | 12 |

| T5 | 270 | 230 | 6 | |

| T6 | 290 | 250 | 6 |

3.1. T4 Temper

The T4 temper represents a solution heat-treated and naturally aged condition. In this state, the alloy has undergone a heat treatment process that dissolves alloying elements, followed by a natural aging period. This results in enhanced ductility and relatively good tensile strength. T4 temper 6082 aluminum is often favored for applications where formability is key. In the production of decorative aluminum profiles, its ability to be easily bent and shaped into intricate designs makes it a top choice. It allows for the creation of ornate details that can add a touch of elegance to any architectural project.

3.2. T5 Temper

T5 temper involves cooling from an elevated temperature after extrusion, followed by artificial aging. This process imparts a balance between strength and formability. The resulting alloy has improved yield strength compared to T4, making it more suitable for load-bearing applications. In aluminum window frames, T5 temper 6082 aluminum can effectively withstand the forces exerted by wind and the weight of the glass, ensuring the integrity of the window over time. It also offers good resistance to thermal expansion and contraction, crucial for maintaining the window's performance in varying weather conditions.

3.3. T6 Temper

T6 temper is achieved through solution heat treatment, quenching, and artificial aging. It yields the highest strength among the three tempers, with excellent tensile and yield strengths. However, this comes at the cost of slightly reduced ductility. T6 temper 6082 aluminum is commonly used in applications where maximum strength is required. For door frames in high-security buildings or industrial settings, the robustness of T6 temper provides an added layer of protection. It can resist forced entry attempts and endure heavy use without significant deformation.

4. Applications in Aluminum Profiles

In the realm of building construction, 6082 aluminum profiles in different tempers offer diverse benefits. For curtain walls, T4 or T5 tempers might be used depending on the design requirements. T4 allows for more creative shapes, while T5 provides better resistance to environmental factors. Window frames often benefit from T5 temper due to its combination of strength and thermal stability.

In industrial applications, T6 temper 6082 aluminum profiles are ideal for machinery frames. They keep the internal components in place and protect them from external impacts. Conveyor systems made from this alloy can withstand the stress of continuous operation, thanks to its excellent strength and wear resistance.

5. Production and Quality Control

To ensure the optimal mechanical properties of 6082 aluminum profiles, manufacturers employ advanced production techniques. The heat treatment process is carefully controlled, with precise temperature and time settings for each temper. During extrusion, the pressure and speed are optimized to ensure uniform microstructure. Quality control measures are implemented at every stage, from raw material inspection to final product testing. This includes checking alloy composition, mechanical properties, and surface quality. By adhering to strict standards, manufacturers can guarantee that each aluminum profile meets or exceeds industry requirements.

6. Future Trends and Innovations

The future of 6082 aluminum looks promising. With the increasing focus on sustainable architecture and energy efficiency, there will likely be a demand for even more optimized alloys and tempers. Research is ongoing to develop new alloy compositions that can further enhance strength while maintaining formability. In the automotive and aerospace industries, 6082 aluminum in advanced tempers could find new applications, driven by the need for lightweight yet strong materials.

7. Conclusion

In conclusion, 6082 aluminum alloy, with its distinct T4, T5, and T6 tempers, offers a remarkable range of mechanical properties that make it a versatile choice for various applications, especially in aluminum profiles for building and industrial use.

At Aluinno, we are committed to leveraging these properties to provide high-quality 6082 aluminum products. Our state-of-the-art facilities and dedicated team ensure that our customers receive the best in terms of both performance and appearance. Whether you are building a new home, renovating an existing structure, or working on an industrial project, trust Aluinno to deliver top-notch 6082 aluminum profiles.

En

En

Location:

Location: