The Mechanical Wonders of 6463 Aluminum in Architectural Elements

In the vibrant world of aluminum alloys, 6463 aluminum has been carving out its own niche, especially when it comes to aluminum profiles that adorn a multitude of structures and products. This alloy has gradually gained recognition from various industries, owing to its unique set of characteristics.

1. Introduction to 6463 Aluminum

6463 aluminum alloy is a member of the 6000 series, renowned for its excellent combination of formability, corrosion resistance, and moderate strength. It is formulated with a precise blend of aluminum and other alloying elements, which have been meticulously selected to achieve the desired properties. Originating from continuous research and development efforts in the aluminum industry, it has found its way into diverse applications, ranging from architectural elements to consumer goods.

2. Fundamentals of Mechanical Properties

The mechanical properties of a material are the bedrock upon which its usability is built. For 6463 aluminum, understanding these properties is crucial. Tensile strength measures the maximum stress a material can endure when pulled apart. It dictates how well the aluminum can withstand stretching forces, which is vital in applications like curtain wall supports or suspended structures. Yield strength, on the other hand, indicates the point at which the material begins to deform permanently. In the context of window frames, for example, it determines the stability of the frame when subjected to wind loads or the force of opening and closing. Ductility, expressed as elongation, showcases the material's ability to stretch without fracturing, enabling complex shaping during the extrusion process.

3. The Prominence of T5 Temper

| ALLOY | STATE | Tensile strength (Rm Mpa) |

Non-proportional Stretching Stress (Rp0.2 Mpa) |

Stretching Rate ((A50mm%)) |

| 6463 | T5 | ≥150 | ≥110 | 6 |

The T5 temper is a key feature of 6463 aluminum that sets it apart in many applications. The heat treatment process for T5 temper involves cooling from an elevated temperature after extrusion, followed by artificial aging. This process imparts a unique combination of properties. Firstly, it enhances the yield strength of the alloy, making it more capable of bearing loads. In window frames, for instance, T5 temper 6463 aluminum can effectively resist the forces exerted by wind and the weight of the glass, ensuring the integrity of the window over time.

Moreover, the T5 temper also improves the surface finish of the aluminum. It results in a smoother and more lustrous appearance, which is highly desirable for decorative applications. When used in trim, moldings, and ornamental pieces, the enhanced surface finish adds an aesthetic appeal, making the final product look more refined and elegant. Additionally, the T5 temper still retains a reasonable level of ductility, allowing for some degree of shaping and customization during fabrication.

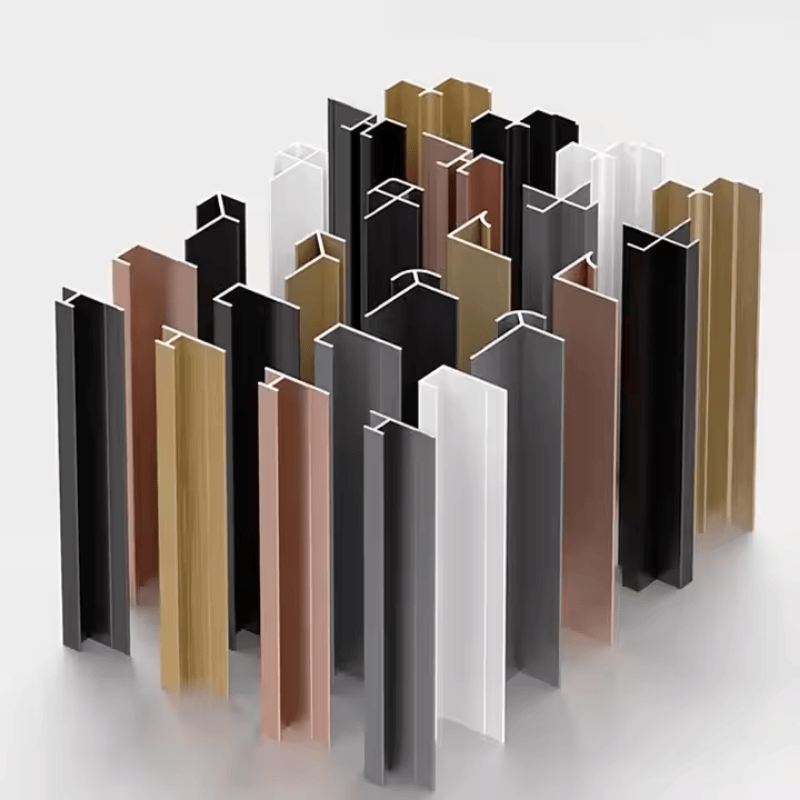

4. Applications in Aluminum Profiles

In the realm of building construction, 6463 aluminum profiles in T5 temper are widely used. For window frames, as mentioned earlier, the combination of strength, corrosion resistance, and excellent surface finish makes it an ideal choice. It not only provides structural support but also enhances the overall look of the building. Doors made from T5 temper 6463 aluminum can withstand the daily wear and tear of opening and closing, while maintaining their appearance.

In decorative applications, the T5 temper really shines. Trim and moldings used in interior and exterior decoration benefit from the smooth surface and the ability to be formed into intricate designs. Ornamental pieces, such as those used in art installations or high-end furniture, can be crafted with precision using 6463 aluminum in T5 temper, adding a touch of sophistication to any setting.

5. Production and Quality Control

To ensure the optimal mechanical properties of 6463 aluminum profiles, manufacturers employ advanced production techniques. The heat treatment process for T5 temper is carefully controlled, with precise temperature and time settings. During extrusion, the pressure and speed are optimized to ensure uniform microstructure. Quality control measures are implemented at every stage, from raw material inspection to final product testing. This includes checking alloy composition, mechanical properties, and surface quality. By adhering to strict standards, manufacturers can guarantee that each aluminum profile meets or exceeds industry requirements.

6. Future Trends and Innovations

The future of 6463 aluminum looks promising. With the increasing focus on sustainable architecture and consumer demand for aesthetically pleasing products, there will likely be a demand for further enhancements in its properties. Research is ongoing to develop new alloy compositions that can improve strength while maintaining formability and surface finish. In emerging fields like 3D printing of aluminum components, 6463 aluminum could potentially find new applications, driven by its unique characteristics.

7. Conclusion

In conclusion, 6463 aluminum alloy, especially in T5 temper, offers a remarkable range of mechanical properties that make it a versatile choice for various applications, especially in aluminum profiles for building and decorative uses.

At Aluinno, we are committed to leveraging these properties to provide high-quality 6463 aluminum products. Our state-of-the-art facilities and dedicated team ensure that our customers receive the best in terms of both performance and appearance. Whether you are building a new home, renovating an existing structure, or working on any project that demands top-notch aluminum, trust Aluinno to deliver.

En

En

Location:

Location: