Mechanical Marvels of 6005 Aluminum Profiles: T5, T6, Solid and Hollow

In the dynamic landscape of the aluminum industry, 6005 aluminum alloy has emerged as a versatile and valuable material, especially when it comes to aluminum profiles. This alloy has found its way into a wide range of applications due to its unique combination of mechanical properties and processability.

1. Introduction to 6005 Aluminum

6005 aluminum alloy belongs to the 6000 series, which is characterized by its good formability, corrosion resistance, and medium - high strength. It is primarily composed of aluminum, with alloying elements such as magnesium and silicon added in specific proportions to achieve the desired properties. The 6005 alloy has gained popularity in various industries because of its ability to meet different performance requirements while maintaining cost - effectiveness.

2. Fundamentals of Mechanical Properties

The mechanical properties of a material are crucial for determining its suitability for different applications. For 6005 aluminum, the key mechanical properties include tensile strength, yield strength, and hardness.

Tensile strength is the maximum stress a material can withstand while being pulled or stretched. It is an important indicator of the material's ability to resist breakage under tension. In applications where the aluminum profile is subjected to pulling forces, such as in suspension bridges or cable - supported structures, high tensile strength is essential.

Yield strength, on the other hand, represents the stress at which a material begins to deform plastically. Once the yield strength is exceeded, the material will not return to its original shape after the load is removed. In structural applications, knowing the yield strength helps engineers design components that can safely carry the intended loads without permanent deformation.

Hardness is a measure of a material's resistance to indentation, scratching, or abrasion. In applications where the aluminum profile is likely to come into contact with hard objects or experience wear and tear, high hardness is desirable. For example, in the transportation industry, where aluminum components may be exposed to road debris or mechanical impacts, hardness is an important property.

3. T5 and T6 Tempers: An In - depth Look

| ALLOY | STATE | Tensile strength (Rm Mpa) |

Non-proportional Stretching Stress (Rp0.2 Mpa) |

Stretching Rate ((A50mm%)) |

|

| 6005 | T5 | 260 | 240 | 6 | |

| T6 | Solid Profiles | 270 | - | 8 | |

| 260 | - | 6 | |||

| 250 | - | 6 | |||

| Hollow profiles | 255 | - | 6 | ||

| 250 | - | 6 | |||

3.1. T5 Temper

The T5 temper of 6005 aluminum involves cooling from an elevated temperature after extrusion, followed by artificial aging. This process results in a material with a good balance of strength and formability. The artificial aging step increases the alloy's yield strength and hardness, making it more suitable for applications that require moderate strength.

In T5 temper, the 6005 aluminum profile has a relatively high level of internal stress relief, which helps to prevent warping and distortion during machining and use. This makes it a popular choice for applications where dimensional stability is important, such as in the production of precision frames and supports.

3.2. T6 Temper

The T6 temper is achieved through solution heat treatment, quenching, and artificial aging. This process imparts the highest strength to the 6005 aluminum alloy. The solution heat treatment dissolves the alloying elements in the aluminum matrix, and the subsequent quenching and aging processes cause the formation of fine - scale precipitates that strengthen the material.

3.3. Comparison between T5 and T6

Compared to T5, T6 temper has higher strength but lower formability. T5 is more suitable for applications where a balance between strength and formability is needed, or where dimensional stability is crucial. T6, especially in solid profiles, is better for heavy - load applications, while hollow T6 profiles are ideal for weight - sensitive applications.

4. Applications in Aluminum Profiles

4.1. Building Construction

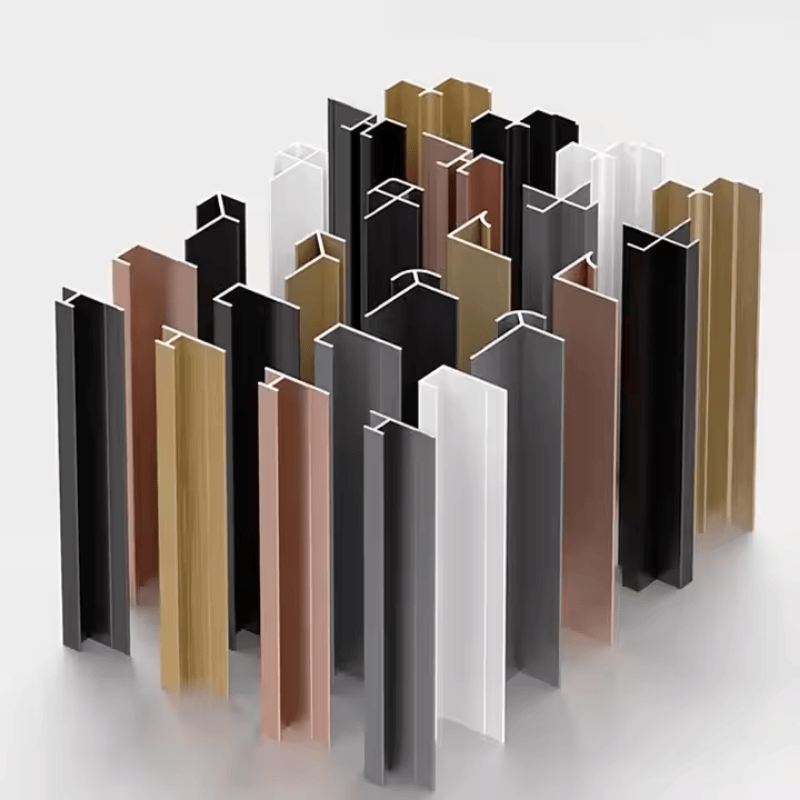

In the building construction industry, 6005 aluminum profiles are widely used. T5 temper profiles are often used for window and door frames, as they can be easily formed into the desired shapes while providing sufficient strength to support the glass and withstand normal operating forces. T6 solid profiles are used for structural supports, such as columns and beams, in large - scale buildings, where high load - bearing capacity is essential. Hollow T6 profiles can be used for curtain walls, which not only provide an aesthetically pleasing appearance but also help to reduce the overall weight of the building.

4.2. Transportation Industry

In the automotive industry, 6005 aluminum profiles are used to reduce the weight of vehicles, which in turn improves fuel efficiency. T6 hollow profiles are commonly used for making automotive frames and structural components, as they offer a good balance between strength and weight. In the railway industry, both T5 and T6 profiles are used for various components, such as carriage frames and supports, to ensure the safety and reliability of trains.

4.3. Other Industrial Applications

In other industrial applications, 6005 aluminum profiles are used in machinery manufacturing, equipment frames, and tooling. T5 profiles are often used for parts that require some formability and moderate strength, while T6 profiles are used for components that need to withstand high - stress conditions.

5. Production and Quality Control

To ensure the optimal mechanical properties of 6005 aluminum profiles, manufacturers employ advanced production techniques. The extrusion process is carefully controlled to ensure uniform cross - sections and proper grain structure. The heat treatment processes for T5 and T6 tempers are also precisely regulated to achieve the desired strength and other properties.

Quality control is an essential part of the production process. Manufacturers conduct various tests, including tensile tests, hardness tests, and chemical composition analysis, to ensure that the profiles meet the required standards. Non - destructive testing methods, such as ultrasonic testing and X - ray inspection, are also used to detect internal defects.

6. Future Trends and Innovations

The future of 6005 aluminum looks promising. With the increasing demand for lightweight and high - strength materials in various industries, there will be continuous efforts to improve the mechanical properties of 6005 aluminum. New alloying elements may be added to further enhance its strength, corrosion resistance, or other performance characteristics.

In addition, advancements in manufacturing technologies, such as additive manufacturing (3D printing), may open up new possibilities for using 6005 aluminum in more complex and customized applications. The development of more precise heat treatment and tempering techniques will also contribute to better - controlled mechanical properties.

7. Conclusion

In conclusion, 6005 aluminum alloy, with its T5 and T6 tempers (including solid and hollow T6 profiles), offers a wide range of mechanical properties that make it suitable for diverse applications. Understanding these properties and choosing the appropriate temper is crucial for achieving the best performance in different scenarios.

At Aluinno, we are dedicated to providing high - quality 6005 aluminum products. Our state - of - the - art facilities and strict quality control measures ensure that our customers receive profiles with excellent mechanical properties and dimensional accuracy. Whether you are in the building construction, transportation, or other industries, you can trust Aluinno to meet your aluminum profile needs.

En

En

Location:

Location: