The Impact of US Tariff Policy on Its Domestic Aluminum Market

1. Introduction

In recent years, the United States has taken significant steps in its trade policy by imposing tariffs on imported aluminum products. This move was primarily driven by the government's intention to safeguard the domestic aluminum industry, which had been facing intense competition from foreign producers, especially those in countries with lower production costs. The tariffs were seen as a way to level the playing field and promote domestic production. However, like any major policy change, the tariff on imported aluminum has had far - reaching consequences for the US domestic aluminum market, affecting not only the producers but also a wide range of downstream industries.

2. Positive Impact on the Domestic Aluminum Industry

Protection of Domestic Producers

The most immediate and obvious benefit of the tariff policy is the protection it offers to domestic aluminum producers. Before the implementation of the tariffs, foreign aluminum products, particularly from countries like China, were flooding the US market at relatively low prices. This put domestic producers at a significant disadvantage, as they struggled to compete on price. With the imposition of tariffs, the cost of imported aluminum increased substantially, making domestic aluminum more price - competitive. As a result, domestic producers have seen an increase in demand for their products, which has helped them to maintain and even expand their production levels.

Capacity Expansion and Job Creation

The increased demand for domestic aluminum has also led to capacity expansion in the industry. Many domestic aluminum producers have invested in new production facilities and upgraded their existing ones to meet the growing demand. This expansion has not only increased the overall production capacity of the US aluminum industry but has also created jobs. From production workers to engineers and managers, the aluminum industry has been able to provide employment opportunities for a significant number of people, contributing to the local and national economies.

3. Negative Impact on Domestic Manufacturers

Cost Increase

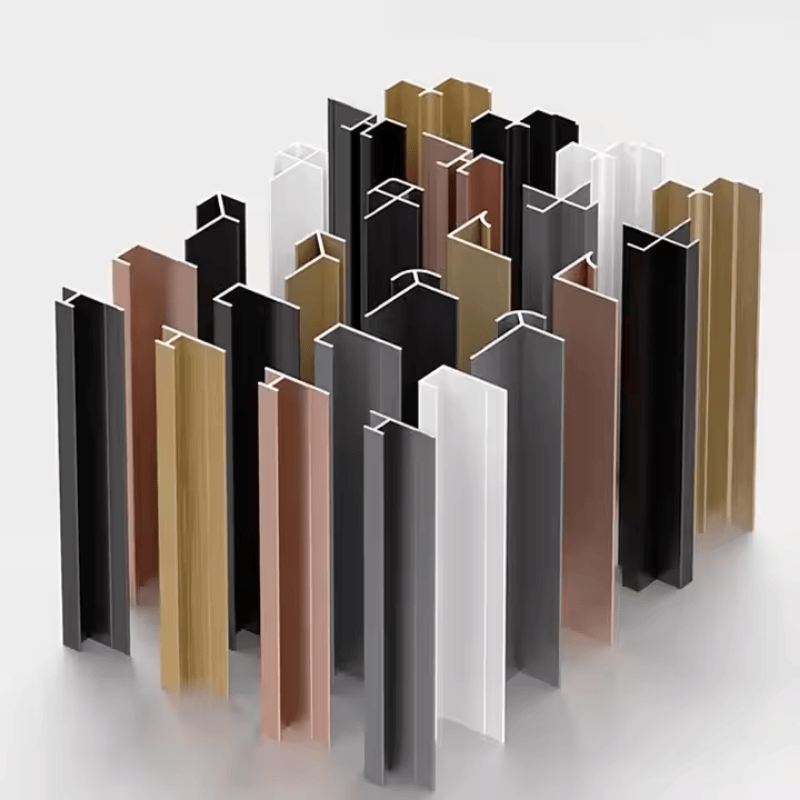

While the tariff policy has been beneficial for domestic aluminum producers, it has had a detrimental effect on domestic manufacturers who rely on imported aluminum as a raw material. These manufacturers, which include those in the aluminum profile and aluminum product sectors, have seen a significant increase in their production costs. The higher cost of imported aluminum has forced them to either absorb the additional cost, which squeezes their profit margins, or pass it on to consumers in the form of higher prices.

Reduced Competitiveness

The increase in production costs has also reduced the competitiveness of domestic manufacturers in both the domestic and international markets. In the domestic market, higher prices for aluminum - based products may lead consumers to choose alternative products or imported goods that are still available at a lower cost. In the international market, US manufacturers are at a disadvantage compared to their foreign counterparts who can access cheaper aluminum raw materials. This has led to a decline in exports of US - made aluminum products, further hurting the domestic manufacturing industry.

4. Impact on Down - stream Industries

Construction Industry

The construction industry is one of the major consumers of aluminum products, including aluminum profiles used in building frames, windows, and doors. The increase in the cost of aluminum has had a direct impact on the construction industry, as construction companies have to pay more for these materials. This has led to an increase in the overall cost of construction projects, which may result in delays or cancellations of some projects. In addition, higher construction costs may also lead to an increase in housing prices, making it more difficult for people to afford new homes.

Automotive Manufacturing

The automotive manufacturing industry also heavily relies on aluminum for various components, such as engine blocks, body panels, and wheels. The increase in the cost of aluminum has added to the production cost of vehicles. Automobile manufacturers may either absorb the cost, which affects their profitability, or pass it on to consumers in the form of higher vehicle prices. Higher vehicle prices may lead to a decrease in demand for new cars, which could have a negative impact on the automotive industry as a whole.

Other Industries

Apart from construction and automotive manufacturing, other industries such as packaging and aerospace also use aluminum products. In the packaging industry, aluminum is widely used for cans and containers. The increase in aluminum prices has led to higher packaging costs, which may be passed on to consumers in the form of higher prices for packaged goods. In the aerospace industry, aluminum is used in aircraft structures. The higher cost of aluminum may lead to an increase in the cost of aircraft production, which could potentially affect the competitiveness of US aerospace companies in the global market.

5. Potential Industrial Structure Adjustment

Shift in Production

The tariff policy may lead to a shift in production patterns within the US aluminum market. Some manufacturers may choose to increase their domestic production of aluminum products to avoid the high cost of imported aluminum. This could lead to a greater reliance on domestic aluminum producers and a reduction in imports. On the other hand, some manufacturers may look for alternative materials to replace aluminum in their production processes. For example, they may switch to steel or composite materials, which could have a long - term impact on the demand for aluminum products.

New Business Models

The challenges posed by the tariff policy may also stimulate the emergence of new business models. For instance, there may be an increased focus on recycling aluminum to reduce the dependence on imported raw materials. Recycling companies may see an opportunity to expand their operations and develop more efficient recycling technologies. In addition, there may be more innovation in the development of new aluminum - based materials or manufacturing processes that can reduce the cost of production and improve the competitiveness of US aluminum products.

6. Conclusion

In conclusion, the US tariff policy on imported aluminum has had a mixed impact on its domestic aluminum market. While it has provided some protection and growth opportunities for domestic aluminum producers, it has also created significant challenges for domestic manufacturers and downstream industries. The increase in production costs has affected the competitiveness of US - made aluminum products and has the potential to disrupt the normal operation of various industries.

To address these issues, the US government may need to re - evaluate its tariff policy and find a more balanced approach that can protect the domestic aluminum industry without causing excessive harm to other sectors. Domestic manufacturers and downstream industries should also explore ways to adapt to the new situation, such as through cost - cutting measures, innovation in materials and processes, and diversification of their supply chains. By working together, the US aluminum - related industries can better navigate the challenges posed by the tariff policy and achieve sustainable development in the long run.

En

En

Location:

Location: